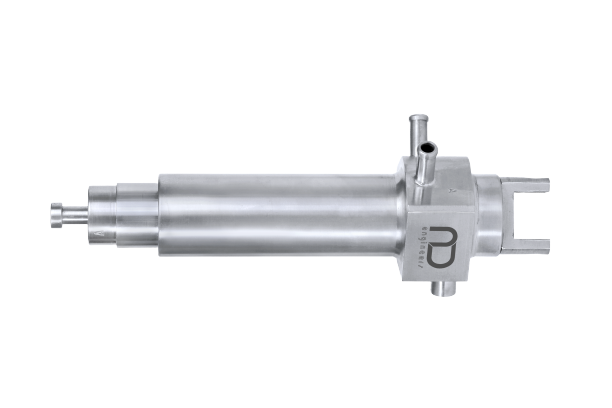

Rotary piston pump for pharmaceutical dosing

Title:

Enhancing Pharmaceutical Processes with Rotary Piston Pumps

Introduction:

In the

pharmaceutical industry, precision and accuracy are of utmost importance. From

dosing medications to filling vials, every step requires meticulous attention

to detail to ensure product quality and patient safety. One critical componentthat plays a crucial role in these processes is the rotary piston pump. In this

blog post, we will explore how pharmaceutical dosing and filling rotary piston

pumps contribute to enhancing efficiency and reliability in pharmaceutical

manufacturing. Whether you are a manufacturer, supplier, or seller in the

industry, understanding the benefits of these pumps can help you better serve

your customers and meet their specific needs.

1. What is

a Rotary Piston Pump?

To lay the

foundation, let's begin by understanding what a rotary piston pump is. A rotary

piston pump is a positive displacement pump that uses rotating pistons to

transfer fluids. It operates by trapping fluid between the rotating pistons and

the pump housing, creating a continuous flow. This mechanism allows for precise

dosing and efficient filling of pharmaceutical products.

2.

Precision Dosing for Pharmaceutical Applications

Accurate

dosing of medications is critical to ensure that patients receive the correct

dosage prescribed by healthcare professionals. Rotary piston pumps offer

exceptional precision, enabling pharmaceutical manufacturers to achieve

consistent dosing accuracy. These pumps are designed to deliver precise

volumes, minimizing variations and reducing the risk of under or overdosing.

3. Reliable

Filling Solutions

In

pharmaceutical manufacturing, proper filling of vials, bottles, or other

containers is crucial to maintain product integrity and prevent contamination.

Rotary piston pumps excel in delivering reliable filling solutions. The

controlled piston movement and consistent flow provided by these pumps ensure a

uniform fill level, reducing wastage and optimizing production efficiency.

4.

Versatile Applications

Rotary

piston pumps find applications across various pharmaceutical processes. They

are commonly used in liquid and semi-solid dosage forms, including syrups,

suspensions, creams, ointments, and more. These pumps can handle a wide range

of viscosities, allowing pharmaceutical manufacturers to accommodate different

product formulations.

5.

High-Quality Manufacturing

When it

comes to pharmaceutical equipment, quality is paramount. Partnering with

reputable rotary piston pump manufacturers ensures that you receive pumps built

to industry standards. Trusted manufacturers employ stringent quality control

measures and adhere to regulatory guidelines, giving you peace of mind about

the reliability and safety of their products.

6. Reliable

Suppliers and Sellers

As a

supplier or seller in the pharmaceutical industry, it is essential to

collaborate with reliable rotary piston pump manufacturers. By establishing

partnerships with trusted suppliers, you can offer high-quality pumps to your

customers, meeting their specific requirements. This ensures customer

satisfaction and enhances your reputation as a reliable source of

pharmaceutical equipment.

7.

Customization and Support

Pharmaceutical

manufacturing processes can vary significantly, with unique requirements for

each product. Reputable rotary piston pump manufacturers understand this and

offer customization options to meet specific needs. Whether it's modifying pump

design, capacity, or material compatibility, manufacturers who provide tailored

solutions can better serve the evolving demands of the pharmaceutical industry.

8.

Compliance with Regulatory Standards

In the

pharmaceutical industry, compliance with regulatory standards is

non-negotiable. When selecting rotary piston pumps, it is crucial to ensure that

they meet industry regulations and guidelines, such as Good Manufacturing

Practices (GMP). Working with manufacturers who prioritize adherence to these

standards helps ensure that your processes remain compliant and your products

meet the required quality and safety standards.

Conclusion:

Pharmaceutical

dosing and filling rotary piston pumps play a vital role in enhancing

pharmaceutical processes. Their precision, reliability, and versatility makethem indispensable in the pharmaceutical manufacturing industry. By partnering

with reputable manufacturers, suppliers, and sellers, you can access

high-quality pumps that meet regulatory standards and provide customized

solutions. Embracing these advanced pumping technologies allows pharmaceutical

companies to optimize their production efficiency, maintain product integrity,

and ultimately contribute to better patient outcomes.

Filter Using Blog Tags