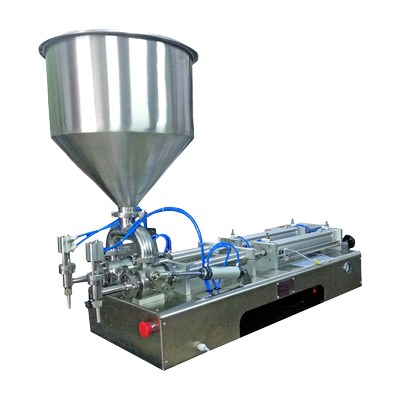

Double Head Pneumatic Paste Filling Machine

A double head pneumatic paste filling machine is a type of filling equipment used to accurately dispense viscous or paste-like substances into containers or packaging. This machine utilizes pneumatic (air pressure) power to drive the filling process and is designed to handle two simultaneous filling heads, allowing for increased efficiency and productivity. Here are the key components and features of a double head pneumatic paste filling machine:

1. Hopper: The machine is equipped with a hopper that holds the paste or viscous substance to be filled. The hopper has a capacity that can vary depending on the specific model and requirements.

2. Filling Heads: A double head machine has two filling heads that operate simultaneously. Each filling head consists of a nozzle or a tube through which the paste is dispensed into the containers. The filling heads are adjustable to accommodate different container sizes and can be easily controlled to achieve accurate filling.

3. Pneumatic Power: The filling process is driven by pneumatic power. Compressed air is used to create pressure within the machine, which forces the paste from the hopper into the containers. Pneumatic power provides consistent and reliable filling, ensuring uniform product quantities in each container.

4. Filling Controls: The machine is equipped with controls to regulate the filling process. These controls allow operators to adjust parameters such as filling volume, filling speed, and filling intervals. This ensures precise and customizable filling according to specific product requirements.

5. Anti-Drip Mechanism: To prevent dripping or excess paste after filling, a double head pneumatic paste filling machine often includes an anti-drip mechanism. This mechanism helps maintain cleanliness and avoids product wastage by retracting the filling nozzle or tube to minimize dripping.

6. Conveyor System: Many double head filling machines are integrated with a conveyor system. This system transports containers to and from the filling heads, ensuring a continuous and automated filling process. The conveyor speed can be adjusted to match the desired production rate.

7. Easy Cleaning and Maintenance: The machine is designed to facilitate easy cleaning and maintenance. Components such as the filling heads, nozzles, and hoppers can be disassembled quickly for cleaning or product changeover. This feature minimizes downtime and ensures hygienic operations.

8. Compatibility with Various Paste Products: Double head pneumatic paste filling machines can handle a wide range of paste-like substances, including creams, gels, sauces, pastes, adhesives, and more. The machine can be configured and customized to suit the specific characteristics of the product being filled.

Double head pneumatic paste filling machines are commonly used in industries such as cosmetics, pharmaceuticals, food and beverage, chemicals, and other manufacturing sectors that require accurate and efficient filling of viscous products. They offer increased productivity, reduced labor costs, and improved product consistency, making them a valuable asset in packaging operations.

Filter Using Blog Tags