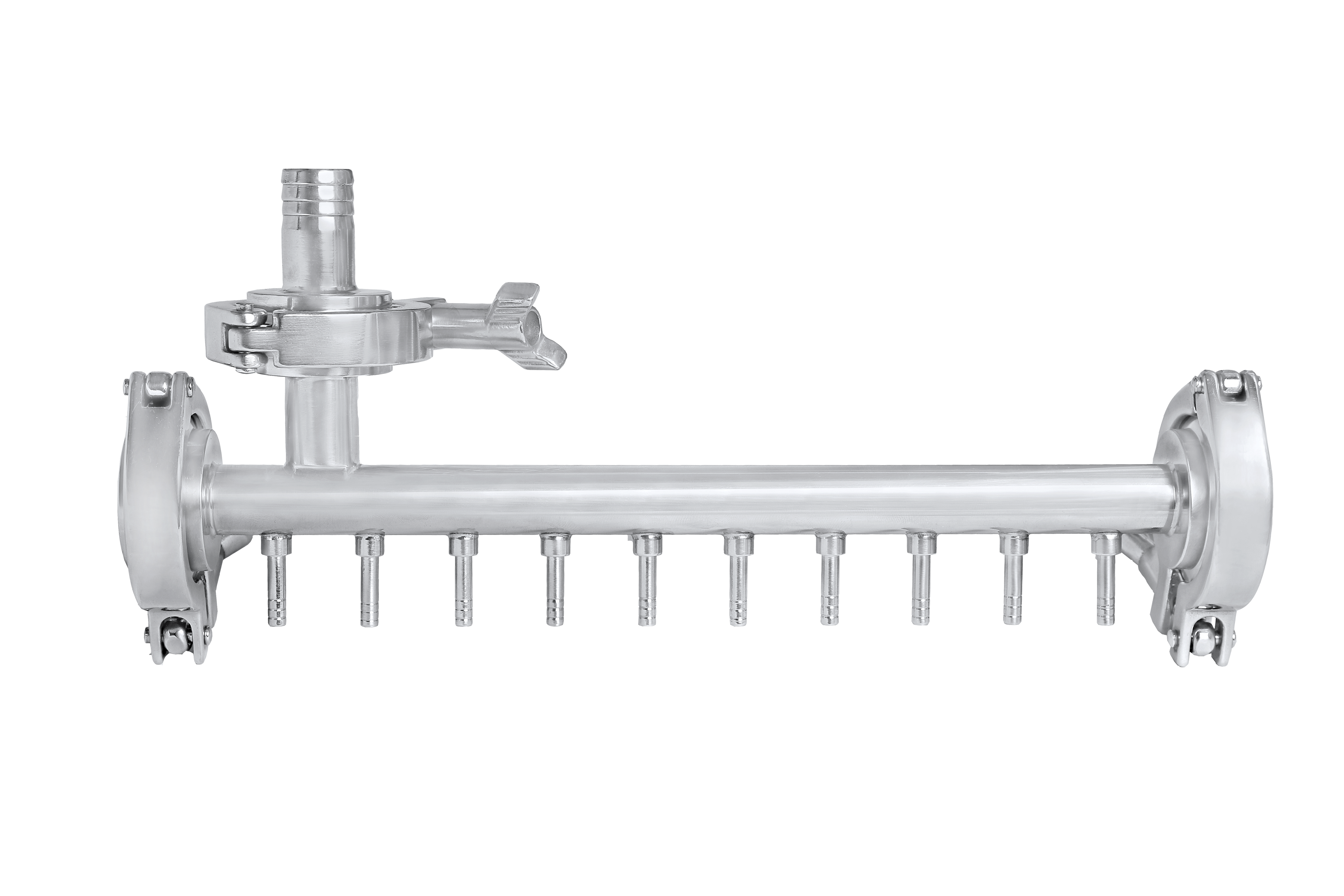

Efficient fluid distribution manifold

Title: The

Advantages of Stainless Steel Manifolds: A Reliable Solution for Fluid

Distribution

Introduction:

In

industrial settings where fluid distribution plays a crucial role, having a

reliable and efficient manifold system is essential. One material that standsout for its durability, versatility, and corrosion resistance is stainless

steel. In this blog post, we will explore the numerous advantages of stainless

steel manifolds and why they are the preferred choice for various applications.

1.

Corrosion Resistance:

Stainless

steel manifolds are highly resistant to corrosion, making them ideal for

handling different types of fluids, including water, chemicals, and gases. This

corrosion resistance ensures a longer lifespan and minimizes the risk of leaks,

protecting both the manifold itself and the surrounding equipment.

2.

Durability and Longevity:

Stainless steel

is renowned for its exceptional strength and durability. Stainless steel

manifolds can withstand high pressures and temperatures, making them suitable

for demanding industrial environments. Their robust construction ensures a

longer lifespan, reducing the need for frequent replacements and maintenance.

3.

Versatility:

Stainless

steel manifolds offer versatility in terms of application. They can be

customized to meet specific requirements, allowing for precise fluid

distribution in various industries such as oil and gas, chemical processing,

HVAC systems, and water treatment. Their adaptability makes them suitable for a

wide range of fluid types and flow rates.

4.

Precision Engineering:

Stainless

steel manifolds are precision-engineered to ensure optimal flow control and

distribution. The smooth internal surfaces of stainless steel minimize

turbulence, pressure drops, and flow restrictions, resulting in improved system

performance and energy efficiency. This precision engineering also allows for

accurate measurement and control of fluid flow.

5. Easy

Maintenance:

Maintaining

stainless steel manifolds is relatively straightforward. Their

corrosion-resistant properties make them easy to clean and disinfect, ensuring

hygienic fluid distribution in applications such as food and beverage

processing or medical equipment. Additionally, stainless steel's non-porous

surface reduces the risk of bacterial growth, enhancing overall system

cleanliness.

6.

Customization Options:

Stainless

steel manifolds can be tailored to specific project requirements. Manufacturers

offer customization options such as size, shape, port configurations, and

mounting methods. This flexibility allows for seamless integration into

existing systems and simplifies installation.

7. Cost-Effectiveness:

Although

stainless steel manifolds may have a higher upfront cost compared to other

materials, their long-term cost-effectiveness outweighs the initial investment.

Their durability and resistance to corrosion minimize maintenance and

replacement expenses, ultimately reducing downtime and increasing operational

efficiency.

Conclusion:

Stainlesssteel manifolds offer a reliable, durable, and versatile solution for fluiddistribution in various industrial applications. Their corrosion resistance, longevity,

precision engineering, and customization options make them the preferred choice

for industries that require efficient and accurate fluid control. Investing in

stainless steel manifolds ensures optimal system performance, reduced

maintenance costs, and increased operational efficiency in the long run.

Filter Using Blog Tags